| Model | CB-36M Belt Type | CB-36M Direct Drive | CB-36Y2M Direct Drive |

|---|---|---|---|

| Controller | Syntec | Syntec | Mitsubishi | Syntec |

| Capacity | |||

| Max. Manu. Dia. | ∅36 (Op: ∅32) mm | ∅36 mm | ∅36 mm |

| Max. Bar Feeding Dia. | ∅36 (Op: ∅32) mm | ∅36 mm | ∅36 mm |

| Axis specifications | |||

| X1/X2-axis travel | 185 / 290 mm | 185 / 290 mm | 185 / 305 mm |

| X/Y/Z-axis rapid travel speed | 30 m/min | 30 m/min | 30 m/min |

| X1/X2-axis motor | 1.3kw / 0.85kw | 1.5 kw / 1.0kw | 1.5 kw / 1.0kw |

| Y1/Y2/Z1/Z2-axis travel | 490/-/165/285 mm | 490/-/165/285 mm | 490 / 54 / 165 / 400 mm |

| Y1/Y2/Z1/Z2-axis motor | Not Y2,0.85kw | Not Y2,1.0 kw | 1.0 / 0.4 / 1.0 / 1.0 kw |

| Min. input unit | 0.001mm | 0.001 mm | 0.001 mm |

| Spindle | |||

| Max. Bar Feeding Dia. | ∅36 (Op: ∅32) mm | ∅36 mm | ∅36 mm |

| Max. speed of spindle | 6000rpm | 6000 rpm | 6000 rpm |

| Center height | 1032 mm | 1032 mm | 1072 mm |

| Spindle collet | TRB-36 (Op: ∅32) | TRB-36 | TRB-36 |

| Min. input unit | 0.001mm | 0.001 mm | 0.001 mm |

| No. of O.D. tools | 6 (Op:5) pcs | 6 (Op:5) pcs | 6 (Op:5) pcs |

| O.D. tool size | □12(Op:□16) mm | □12(Op:□16) mm | □12(Op:□16) mm |

| No. of I.D. tools | 5 pcs | 5 pcs | 5 pcs |

| I.D. tool size | ∅25 mm | ∅25 mm | ∅25 mm |

| Spindle motor | 7.5 kw | 7.9 kw | 7.9 kw |

| Spindle live tooling | |||

| No. of radial live tooling | 4 pcs | 4 pcs | 4 pcs |

| Radial live tooling size | ER-20 | ER-20 | ER-20 |

| Radial live tooling motor | 1.5 kw | 1.5 kw | 1.5 kw |

| Max. speed of radial live tooling | 6000 rpm | 6000 rpm | 6000 rpm |

| No. of axial live tooling | 3 pcs | 3 pcs | 3 pcs |

| Axial live tooling size | ER-20 | ER-20 | ER-20 |

| Axial live tooling motor | 0.75 kw | 0.75 kw | 0.75 kw |

| Max. speed of axial live tooling | 6000 rpm | 6000 rpm | 6000 rpm |

| Sub Spindle | |||

| Max. bar feeding dia. | ∅27.5 mm | ∅36 mm | ∅36 mm |

| Max. speed of sub spindle | 6000 rpm | 6000 rpm | 6000 rpm |

| Sub spindle collet | TRB-32 | TRB-36 | TRB-36 |

| No. of turning tool | 4 pcs | 4 pcs | 4 pcs |

| I.D. tool size | ∅25 mm | ∅25 mm | ∅16 / ER-16 |

| Sub spindle servo motor | 4.4 kw | 7.9 kw | 7.9 kw |

| C-axis index positioning | 0.001° | 0.001° | 0.001° |

| Sub spindle live tooling | |||

| No. of axial live tools | 4 pcs | 4 pcs | 8 pcs |

| Axial live tooling motor | 0.75 kw | 0.75 kw | 0.75 kw |

| Max. speed of axial live tooling | 6000 rpm | 6000 rpm | 6000 rpm |

| Hydraulic unit | |||

| Hydraulic pump | 1HP/0.75kw | 1HP/0.75kw | 1HP/0.75kw |

| Hydraulic tank | 46 L | 46 L | 46 L |

| Coolant Pump | |||

| Main & Sub spindle upper flush pump | 1HP/0.75 kw | 1HP/0.75 kw | 1HP/0.75 kw |

| Tool coolant pump | 1HP/0.75 kw | 1HP/0.75 kw | 1HP/0.75 kw |

| Coolant tank | 240 L | 240 L | 240 L |

| Machine | |||

| Voltage stabilizer / Transformer | 220V / 20 KVA | 220V / 20KVA | 220V / 31KVA |

| Machine size(LxWxH) | 3029x1612x2151 mm | 3029x1612x2151 mm | 3233x1655x2053 mm |

| Machine weight | 4000 kg Machine:3850 kg | 4000 kg Machine:3850 kg | 4000 kg Machine:3850 kg |

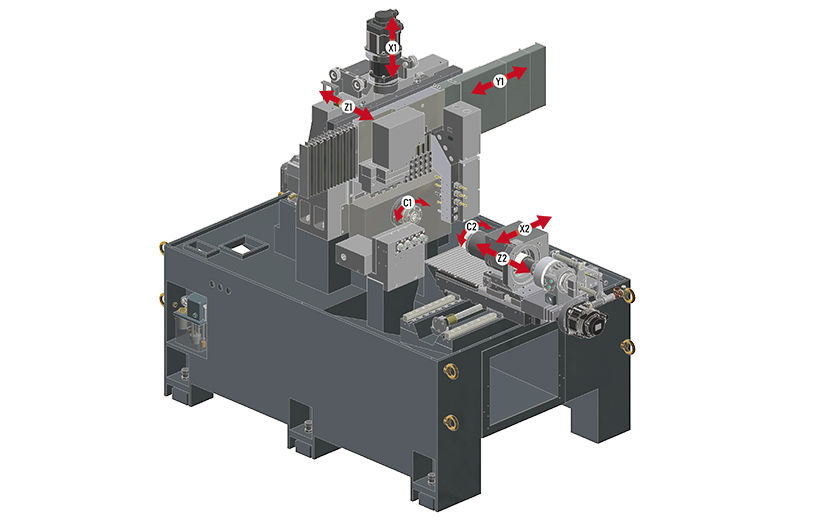

Sliding Head - CB-36M

1. A combination of main and sub-spindle

2. ∅32/36 mm bar capacity

3. X, Y, Z-axis rapid traverses 30m/min

4. Linear ways on 5 axes

5. PC-based control

6. Collet chucking system

7. Finished parts catcher and conveyor

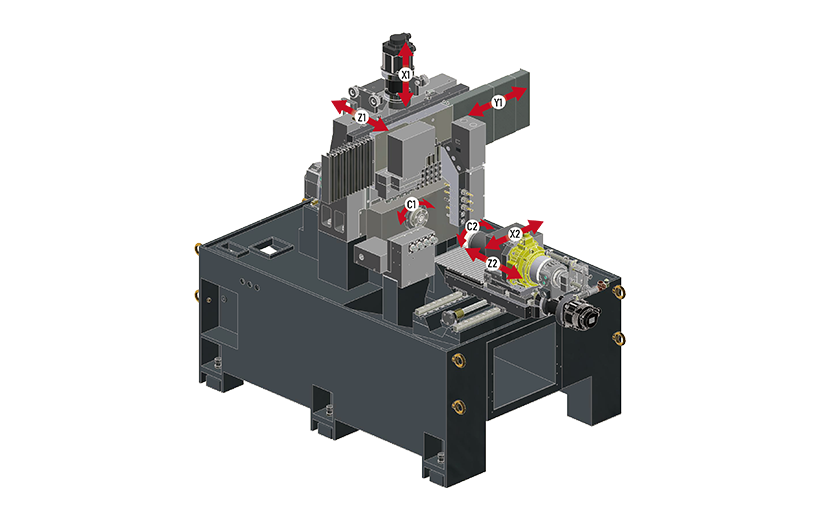

Direct Drive

Enhanced roundness and accuracy are achieved, as there are no gears or belts causing vibrations.

2. ∅32/36 mm bar capacity

3. X, Y, Z-axis rapid traverses 30m/min

4. Linear ways on 5 axes

5. PC-based control

6. Collet chucking system

7. Finished parts catcher and conveyor

Direct Drive

Enhanced roundness and accuracy are achieved, as there are no gears or belts causing vibrations.

Features

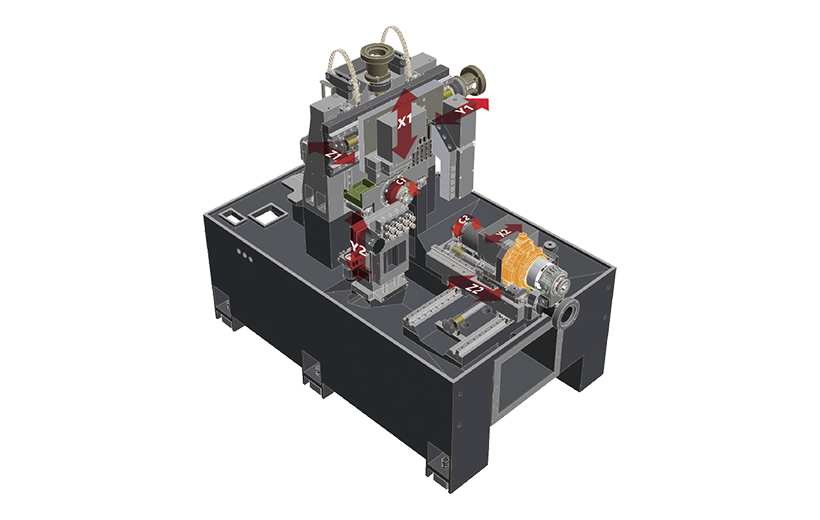

- Sliding Head without Guide Bush:

- The spindle head moves on two precision extra large span linear guide ways, exhibiting outstanding stability and high positioning accuracy.

- Faster Setups

- Accommodate No-Grind Stock for Saving Cost

- No Guide Bush equals Shorter Remnants Limited to Collet

- Length

- Back Milling Device:

- Back milling and drilling for complicated parts does not need secondary setups thus saving time and labor costs.

- Auto Screw Chip Conveyor & Cart

- Steel Belt Chip Conveyor & Cart

- Voltage Stabilizer / Transformer

- High Pressure Coolant Device

- Gripper Device

- Bar Feeder

Applications

- Specification

- Optional

Search

Optional

- Auto screw chip conveyor & cart

- High pressure coolant device

- Steel belt chip conveyor & cart

- Gripper device

- Voltage stabilizer / transformer

- Bar feeder