| Model | C-428T(S) / C-528T(S) | C-4212T(S) / C-5212T(S) |

|---|---|---|

| Capacity | ||

| Controller | Mitsubishi | Fanuci | Mitsubishi | Fanuc |

| Max. manu. dia. | ∅160 mm | ∅160 mm |

| Swing over bed dia. | ∅420 mm | ∅420 mm |

| Max. turning. length | 280 mm | 280 mm |

| Axis specifications | ||

| X-axis travel | 120 mm | 120 mm |

| Z-axis travel | 350 mm | 350 mm |

| X/Z-axis motor | M:1.0 / 1.5 kw | F:1.2 / 1.2 kw | M:1.0 / 1.5 kw | F:1.2 / 1.2 kw |

| X-axis rapid travel speed | 12 m/min | 12 m/min |

| Z-axis rapid travel speed | 18 m/min | 18 m/min |

| Min. input unit | 0.001 mm | 0.001 mm |

| Spindle | ||

| Max. bar feeding dia. | #42:Ø42mm | #52:Ø51mm | #42:Ø42mm | #52:Ø51mm |

| Max. speed of spindle | 4000 rpm(Op:6000rpm) | 4000 rpm(Op:6000rpm) |

| Spindle chuck | 6 | 6 |

| Spindle motor | M:5.5 / 7.5 kw | F:7.5 / 11 kw | M:5.5 / 7.5 kw | F:7.5 / 11 kw |

| Spindle nose | A2-5 | A2-5 |

| Taper of Spindle Bore | MT#6 | MT#6 |

| Spindle collet | TRB-42 / TRB-52 | TRB-42 / TRB-52 |

| Turret | ||

| O.D. tool size | □20 mm | □20 mm |

| I.D. tool size | ∅25 mm | ∅25 mm |

| Live tool turret | ||

| No. of live tool | 8 | 12 |

| Turret Motor | 0.85 kw | 0.85 kw |

| Hydraulic unit | ||

| Hydraulic pump | 1HP/0.75 kw | 1HP/0.75 kw |

| Coolant Pump | ||

| Main & Sub spindle upper flush pump | 3/4HP / 0.53 kw | 3/4HP / 0.53 kw |

| Turret coolant pump | 3/4HP / 0.53 kw | |

| Tank capacity | ||

| Hydraulic tan | 20 L | 20 L |

| Coolant tank | 110 L | 110 L |

| Machine | ||

| Voltage stabilizer / transformer | 220V / 15KVA | 220V / 20KVA |

| Auto Lubricator | 3~6cc / 10min | 3~6cc / 10min |

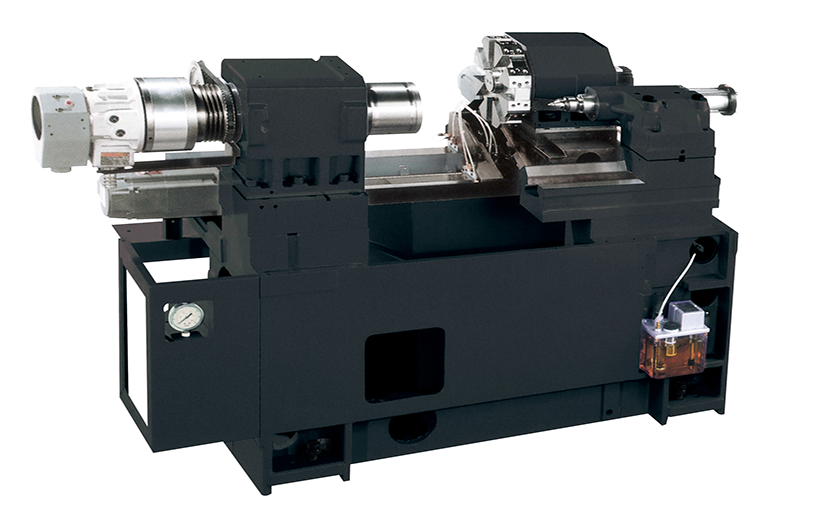

| Machine size(LxWxH) (includes chip conveyor) | 2985x1470x1650 mm | 2985x1470x1650 mm |

| Machine N.W. (includes chip conveyor) | 2200 kg Machine:2055 kg | 2300kg Machine:2155 kg |

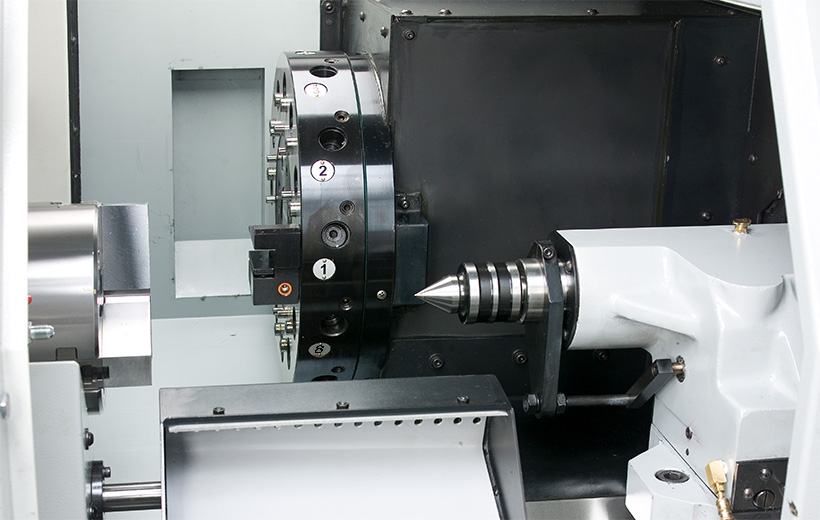

Turret Type - C-428T(S) / C-4212T(S)

1. Servo / power turret

2. C-axis precision machining

3. Capable of 8 or 12 tool stations

2. C-axis precision machining

3. Capable of 8 or 12 tool stations

Features

- Specially Designed Spindle:

- Specially designed spindle with high torque and constant speed, enhances rigidity even at low speeds. Heavy duty work capability and extreme precision cutting all in one machine.

- Hydraulic Tailstock:

- Hydraulic tailstock(option) designed for versatile functions such as turning the longer parts whilst maintaining high stability.

Applications

- Specification

- Optional

Search

Optional

- Steel belt chip conveyor & cart

- High pressure coolant device

- Tailstock

- Oil mist Re-collector

- Auger type chip conveyor & cart

- Finished parts catcher & conveyor

- Auto parts catcher

- High pressure coolant device

- Volteage stabilizer / trans for mer

- 6" hydraulic chuck

- Robot