| Model | NCY-32M | NCY-36M |

|---|---|---|

| Capacity | ||

| Controller | Syntec | Syntec |

| Max. turning. dia. | ∅32 mm | ∅36 mm |

| Axis specifications | ||

| X/Y/Z-axis travel | 190 / 490 / 165 mm | 190 / 490 / 165 mm |

| X/Y/Z-axis motor | 1.3kw / 0.85kw / 0.85kw | 1.3kw / 0.85kw / 0.85kw |

| X/Y/Z-axis rapid travel speed | 30m/min | 30m/min |

| Spindle | ||

| Max. bar feeding dia. | ∅32 mm | ∅36 mm |

| Max. speed of spindle | St:4500 / Op:6000 rpm | St:4500 / Op:6000 rpm |

| Center height | 1015 mm | 1015 mm |

| Spindle collet | TRB-32 | TRB-36 |

| No. of O.D. tools | 6 (Op:5) | 6 (Op:5) |

| O.D. tool size | □12 mm(Op:□16 mm) | □12 mm(Op:□16 mm) |

| No. of I.D. tools | 5 | 5 |

| I.D. tool size | ∅25 mm | ∅25 mm |

| Spindle motor | 7.5 kw | 7.5 kw |

| Live tooling | ||

| No. of radial live tooling | 4 | 4 |

| Radial live tooling size | ER-20 | ER-20 |

| Radial live tooling motor | 1.5 kw | 1.5 kw |

| Max. speed of radial live tooling | 6000 rpm | 6000 rpm |

| No. of axial live tooling | 3 | 3 |

| Axial live tooling size | ER-20 | ER-20 |

| Axial live tooling motor | 0.75 kw | 0.75 kw |

| Max. speed of axial live tooling | 6000 rpm | 6000 rpm |

| Power | ||

| Voltage stabilizer / transformer | 220V / 20KVA | 220V / 20KVA |

| Spindle upper flush pump | 1HP / 0.75 kw | 1HP / 0.75 kw |

| Tool coolant pump | 1HP / 0.75 kw | 1HP / 0.75 kw |

| Hydraulic Motor | 1HP / 0.75 kw | 1HP / 0.75 kw |

| Tank capacity | ||

| Hydraulic tank | 28L | 28L |

| Coolant tank | 240L | 240L |

| Machine | ||

| Machine size(LxWxH) (includes chip conveyor) | 2442x1954x1722 mm | 2442x1954x1722 mm |

| Machine N.W.(includes chip conveyor) | 3100 kg Machine:2940 kg | 3100 kg Machine:2940 kg |

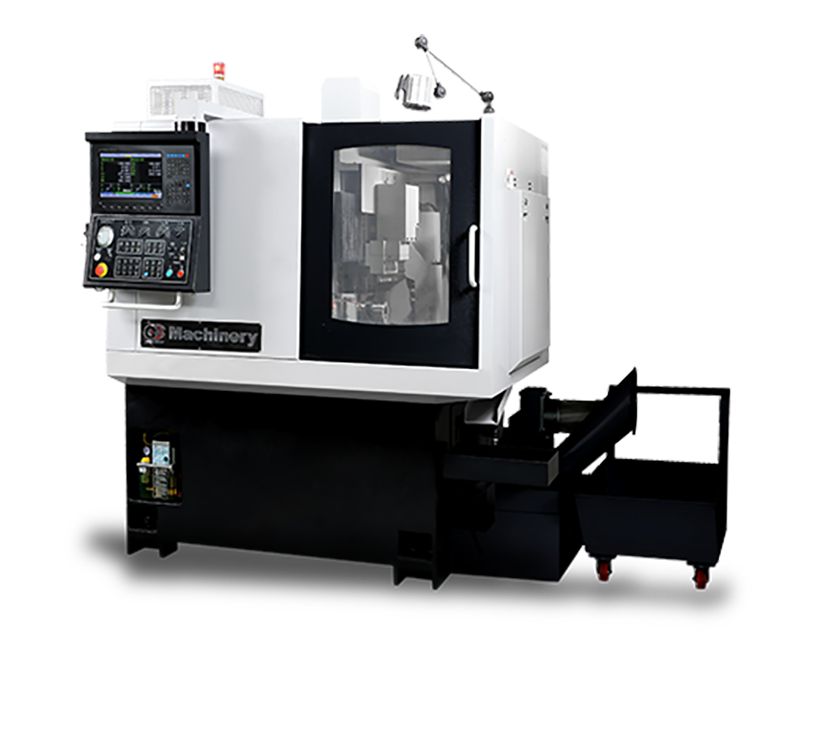

Sliding Head - NCY

Sliding headstock design

∅32/36 mm bar capacity

X, Y, Z-axis rapid traverses 30m/min

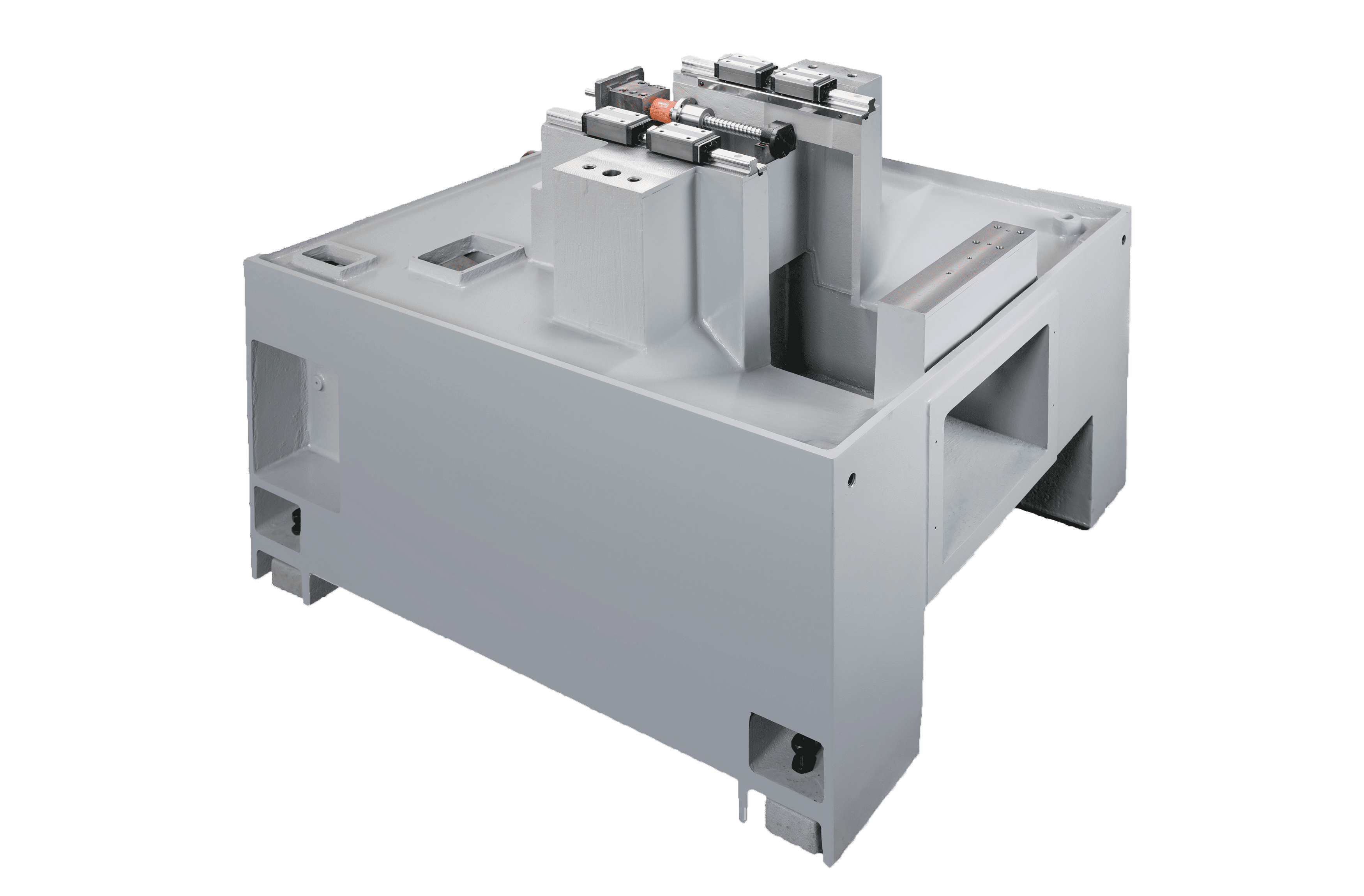

Linear ways on X, Y, Z-axes

6,000 rpm spindle is optional

PC-based CNC control

Reggedly constructed cast iron base

∅32/36 mm bar capacity

X, Y, Z-axis rapid traverses 30m/min

Linear ways on X, Y, Z-axes

6,000 rpm spindle is optional

PC-based CNC control

Reggedly constructed cast iron base

Features

- Side Milling Device

- Total of 4 Servo Motor Driven Power Tools

- End Milling Device

- Total of 8 Tools- 3 Powered and 5 Static

- Tailstock

- With the optional auxiliary tailstock the machine is able to cut longer parts, and the ruggedly constructed tailstock holds each part firmly in place.

Applications

- Specification

- Optional

Search

Optional

- Cross side turning tool device

- Steel belt chip conveyor & cart

- Air-blowing device

- Front side turning tool device

- Voltage stabilizer / transformer

- Spindle motor up to 6000rpm

- Auto spiral chip conveyor & cart

- Tailstock

- Spindle motor upgraded to 5 kW & 4000rpm