| Model | CT2-52 | CT2-52YM | CT2-52Y2M(S) | CT2-76YM | CT2-76Y2M |

|---|---|---|---|---|---|

| Controller | Mitsubishi | Mitsubishi | Fanuc | Mitsubishi | Fanuc | Mitsubishi | Fanuc | Mitsubishi | Fanuc |

| Max. turning. dia | Ø 325 mm | Ø 325 mm | Ø 325 mm | Ø 325 mm | Ø 325 mm |

| Standard turning. dia. | Ø 210 mm | Ø 210 mm | Ø 210 mm | Ø 210 mm | Ø 210 mm |

| Swing over bed dia. | Ø 830 mm | Ø 830 mm | Ø 830 mm | Ø 830 mm | Ø 830 mm |

| Max. turning. length | 400 mm | 440 mm | 310 mm | 415 mm | 285 mm |

| Bar capacity | Ø 51 mm | Ø 51 mm | Ø 51 mm | Ø 76 mm | Ø 76 mm |

| Distance between two center | 920 mm | 920 mm | 1045 mm | 920 mm | 1045 mm |

| Axis specifications | |||||

| B-axis travel | 650 mm | 650 mm | 775 mm | 530 mm | 655 mm |

| Z1/Z2/Z3-axis travel | 440 / 440 mm | 440 / 440 mm | 310 / 250 mm | 382 / 382 mm | 252 / 250 mm |

| X1/X2/X3-axis travel | 227.5 / 232 mm | 227.5 / 230 mm | 227.5 / 227.5 mm | 227.5 / 230 mm | 227.5 / 227.5 mm |

| Y1/Y2-axis travel | - | ± 50 mm | ± 50 / ± 50 mm | ± 50 mm | ± 50 / ± 50 mm |

| X/Y/Z-axis rapid travel speed | 16 / 6 / 40 m/min | 16 / 6 / 40 m/min | 16 / 6 / 40 m/min | 16 / 6 / 40 m/min | 16 / 6 / 40 m/min |

| B-axis motor | 40 m/min | 40 m/min | 40 m/min | 40 m/min | 40 m/min |

| Min. input unit | 0.001 mm | 0.001 mm | 0.001 mm | ||

| Spindle | |||||

| Max. speed of spindle | 4000rpm (Op:6000 rpm) | 4000rpm (Op:6000 rpm) | 4000rpm (Op:6000 rpm) | 4000 rpm | 4000 rpm |

| Spindle motor | M: 7.5 / 11 kw | F :11 / 15 kw | M: 7.5 / 11 kw | F :11 / 15 kw | M: 7.5 / 11 kw | F :11 / 15 kw | M: 15 / 22 kw | F: 18 / 22 kw | M: 15 / 22 kw | F: 18 / 22 kw |

| Center height | 1188 mm | 1188 mm | 1188 mm | 1188 mm | 1188 mm |

| Spindle bore | Ø60.5 mm | Ø60.5 mm | Ø60.5 mm | Ø88 mm | Ø88 mm |

| Spindle nose | A2-5 | A2-5 | A2-5 | A2-6 | A2-6 |

| Spindle bearing dia. | Ø90 mm | Ø90 mm | Ø90 mm | Ø120 mm | Ø120 mm |

| Chuck size | 6" | 6" | 6" | 8" | 8" |

| Spindle bar capacity | Ø51 mm | Ø51 mm | Ø51 mm | Ø76 mm | Ø76 mm |

| Sub spindle | |||||

| Max. speed of sub spindle | 4000rpm (Op:6000 rpm) | 4000rpm (Op:6000 rpm) | 4000rpm (Op:6000 rpm) | 4000 rpm | 4000 rpm |

| Sub spindle motor | M: 7.5 / 11 kw | F :11 / 15 kw | M: 7.5 / 11 kw | F :11 / 15 kw | M: 7.5 / 11 kw | F :11 / 15 kw | M: 7.5 / 11 kw | F: 18 / 22 kw | M: 7.5 / 11 kw | F: 18 / 22 kw |

| Sub spindle nose | A2-5 | A2-5 | A2-5 | A2-6 | A2-6 |

| Sub spindle bore | Ø 60.5 mm | Ø 60.5 mm | Ø 60.5 mm | Ø 88 mm | Ø 88 mm |

| Spindle bar capacity | Ø 51 mm | Ø 51 mm | Ø 51 mm | Ø 65 mm | Ø 65 mm |

| Chuck size | 6" | 6" | 6" | 8" | 8" |

| L, R, C | |||||

| Min. moving unit | 0.001° | 0.001° | 0.001° | 0.001° | 0.001° |

| C-axis rapid travel rate | 600 min⁻¹ | 600 min⁻¹ | 600 min⁻¹ | 600 min⁻¹ | 600 min⁻¹ |

| Live tool turret | |||||

| Turret station | 16-station | 16-station | 16-station | 16-station | 16-station |

| O.D. tool | □25 mm | □25 mm | □25 mm | □25 mm | □25 mm |

| I.D. tool | Ø 25 mm | Ø 25 mm | Ø 25 mm | Ø 25 mm | Ø 25 mm |

| Rotating mode | - | Single tool transmission | Single tool transmission | Single tool transmission | Single tool transmission |

| Live tool rpm | - | 60~6000 min⁻¹ | 60~6000 min⁻¹ | 60~6000 min⁻¹ | 60~6000 min⁻¹ |

| Live tool motor | - | M: 3.7 / 5.5 kw | F: 4.5 kw | M: 3.7 / 5.5 kw | F: 4.5 kw | M: 3.7 / 5.5 kw | F: 4.5 kw | M: 3.7 / 5.5 kw | F: 4.5 kw |

| No. of live tool | - | 16×2 | 16×2 | 16×2 | |

| Collet size | ERØ32 | ERØ32 | ERØ32 | ERØ32 | ERØ32 |

| Tool holder & tool size | - | BMT65 | BMT65 | BMT65 | BMT65 |

| Power | |||||

| Voltage stabilizer / transformer | 60KVA | 60KVA | 60KVA | 60KVA | 60KVA |

| Hydraulic motor | 5HP / 3.7kw | 5HP / 3.7kw | 5HP / 3.7kw | 5HP / 3.7kw | 5HP / 3.7kw |

| Coolant motor | 1HP / 0.75kw | 1HP / 0.75kw | 1HP / 0.75kw | 1HP / 0.75kw | 1HP / 0.75kw |

| Tank capacity | |||||

| Hydraulic tank | 48 L | 48 L | 48 L | 48 L | 48 L |

| Coolant tank | 360 L | 360 L | 360 L | 360 L | 360 L |

| Machine | |||||

| Machine size(LxWxH) (includes chip conveyor) | 4216x2342x2144 mm | 4216x2342x2144 mm | 4185x2085x2154 mm | 4216x2342x2144 mm | 4327x2335x2164 mm |

| Machine N.W.(includes chip conveyor) | 10200 kg Machine: 9732 kg | 10200 kg Machine: 9732 kg | 10200 kg Machine: 9985 kg | 10300 kg Machine: 9832 kg | 11200 kg Machine:10915 kg |

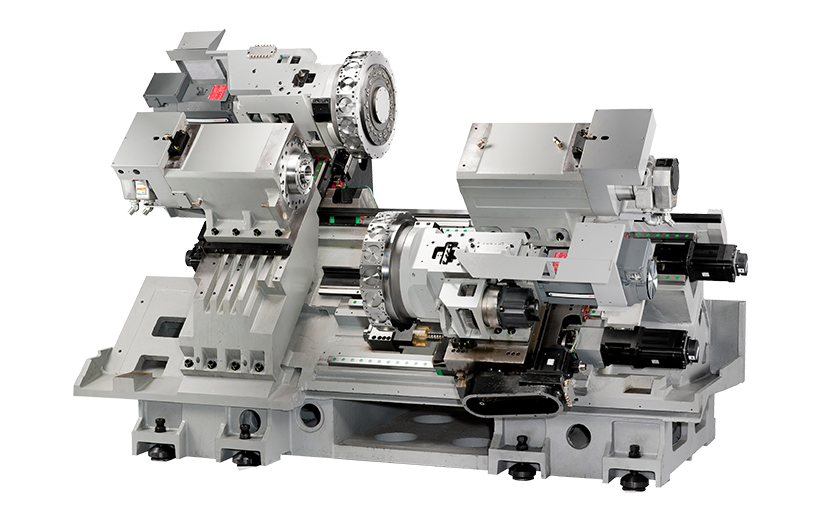

Turret Type - CT2

1. Double Turret with 16-station Live Tooling

2. Double Built-in Spindle

3. Single Y-axis (upper servo turret and lower servo turret design)

4. Double Y-axis ( 2 upper servo turret design)

2. Double Built-in Spindle

3. Single Y-axis (upper servo turret and lower servo turret design)

4. Double Y-axis ( 2 upper servo turret design)

Features

- Double Y-axis:

- Tailstock Option:

- With CT2-52Y2MS CNC milling turning center both turrets are located at the top of the machine to allow customers the option of a central tailstock for longer work piece stability.

- Built-in Type Spindle:

- The built-in spindle performing short accelerate/decelerate time and low vibration characteristic, it provide high precision and high efficient capability.

- Oil Mist Lube System:

- The oil mist lube system provides lubrication oil for the gears in the turret, that supply for reducing the mist continuously and lower the temperature of gear.

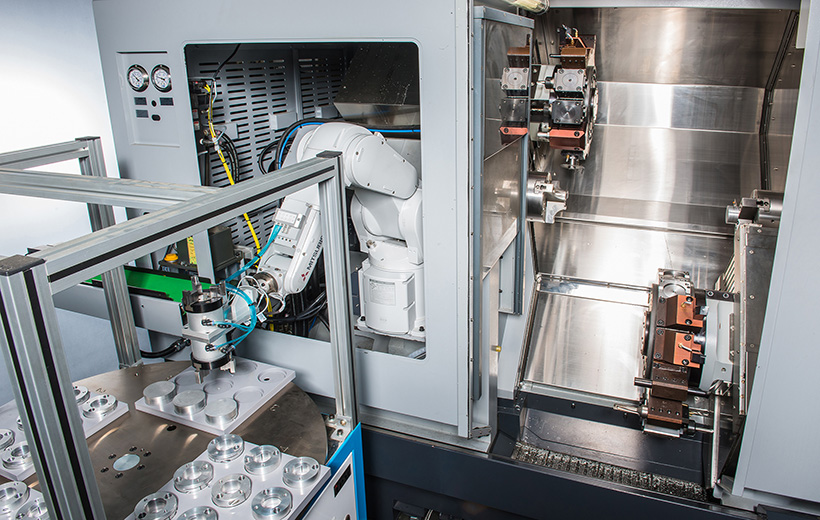

- Cell Automation Options:

- We now offers two options for cell automation in the CT series machines. So for customers operating in multi cell environments you can choose either a gantry type loader/unloader or a fully robotic arm.

Applications

- Specification

- Optional

Search

Optional

- 6"/8" Hydraulic Chuck

- Voltage Stabilizer

- Spindle Chiller Device

- Oil Mist Collector

- Mitsubishi Robot

- Axial And Radial Live Tool Holder

- 15-Bar High Pressure Coolant Device With Filter

- Bar Feeder

- Automatic Door Device

- Gantry System