| Model | CT1-76YM | CT1-76 |

|---|---|---|

| Capacity | ||

| Controller | Mitsubishi | Fanuc | Mitsubishi | Fanuc |

| Max. manu. dia. | Ø 325 mm | Ø 325 mm |

| Standard turning. dia. | Ø 210 mm | Ø 210 mm |

| Max. turning. length | 560 mm | 560 mm |

| Bar capacity | Ø 76 mm | Ø 76 mm |

| Axis specifications | ||

| X1/Y1/Z1-axis travel | 225 / ± 50 / 636 mm | X1:225 / Z1:636 mm |

| X1/Y1/Z1-axis motor | M: 2.2 kw / F:2.7 kw | M:X1.Z1: 2.2 kw / F:X1.Z1: 2.7 kw |

| X1/Y1/Z1-axis rapid travel speed | 16 / 6 / 40 m/min | X1:16 / Z1:40 m/min |

| B-axis motor | 690.5 mm | 690.5 mm |

| B-axis motor | M: 2.2 kw / F:2.7 kw | M: 2.2 kw / F:2.7 kw |

| B-axis rapid travel speed | 40 m/min | 40 m/min |

| Min. input unit | 0.001 mm | 0.001 mm |

| Spindle | ||

| Max. bar feeding dia. | Ø 76 mm | Ø 76 mm |

| Max. speed of spindle | 4000 rpm | 4000 rpm |

| Spindle motor | M:15/22 kw F:18/22 kw | M:15/22 kw F:18/22 kw |

| Center height | 1000 mm | 1000 mm |

| Spindle nose | A2-6 | A2-6 |

| Chuck size | 8" | 8" |

| Sub spindle | ||

| Max. bar feeding dia. | Ø 65 mm | Ø 65 mm |

| Max. speed of spindle | 4000 rpm | 4000 rpm |

| Sub spindle motor | M:7.5/11 kw F:18/22kw | M:7.5/11 kw F:18/22kw |

| Sub spindle nose | A2-6 | A2-6 |

| Sub chuck size | 8" | 8" |

| L, R, C | ||

| Min. moving unit | 0.001° | 0.001° |

| C-axis rapid travel rate | 600 min⁻¹ | 600 min⁻¹ |

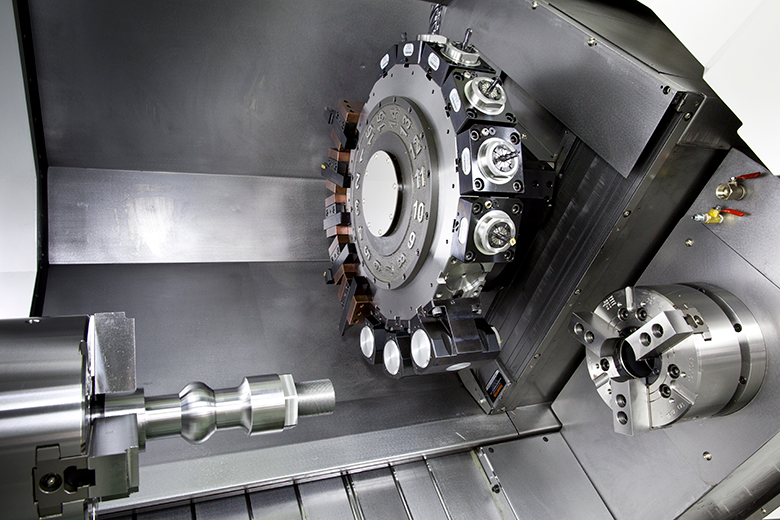

| Live tool turret | ||

| Turret station | 16-station | 16-station |

| O.D. tool | □25 mm | □25 mm |

| I.D. tool | Ø 25 mm | Ø 25 mm |

| Rotating mode | Single tool transmission | - |

| Live tool rpm | 60~6000 min⁻¹ | - |

| Live tool motor | M:3.7/5.5 kw F:4.5kw | - |

| No. of live tool | 16 | 16 |

| Collet size | ERØ32 | ERØ32 |

| Tool holder & tool size | BMT65 | - |

| Hydraulic unit | ||

| Hydraulic pump | 5HP / 3.7 kw | 5HP / 3.7 kw |

| Coolant Pump | ||

| Spindle upper flush pump | 1HP / 0.75kw | 1HP / 0.75kw |

| Turret coolant pump | 1HP / 0.75kw | 1HP / 0.75kw |

| Chip flush pump | 1HP / 0.75kw | 1HP / 0.75kw |

| Sub-spindle internal coolant pump | 1HP / 0.75kw | 1HP / 0.75kw |

| Tank capacity | ||

| Hydraulic tank | 45 L | 45 L |

| Coolant tank | 325 L | 325 L |

| Machine | ||

| Voltage stabilizer / transformer | 220V / 45KVA | 220V / 45KVA |

| Machine size(LxWxH) (includes chip conveyor) | 4779x2086x2061 mm | 4779x2086x2061 mm |

| Machine N.W.(includes chip conveyor) | 8000kg Machine:7715kg | 8000kg Machine:7715kg |

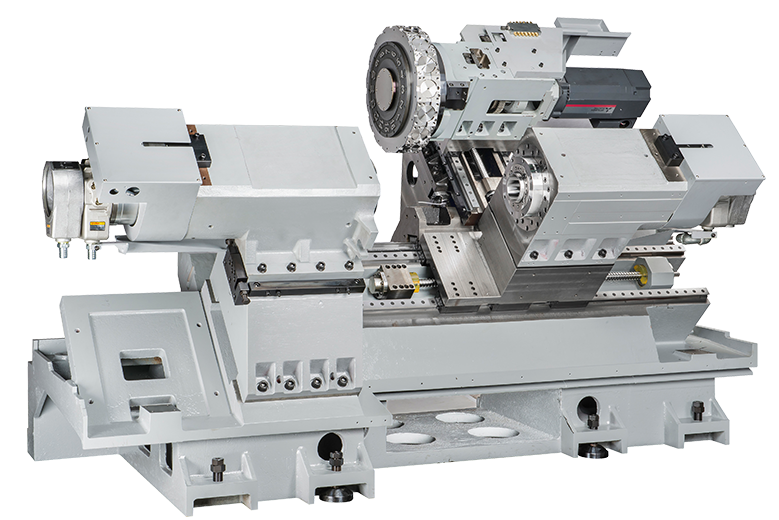

Turret Type-CT1

1. Y-Axis Turret

2. 76mm Built-in Spindle

3. Double Spindle Versatility

2. 76mm Built-in Spindle

3. Double Spindle Versatility

Features

- ˙The CT1's double spindle design allows for the cutting of complex parts in a single setup, and coupled with a 16-station turret.

- ˙When the Y-Axis turret is in the upper position, it can complete machining on parts in the main or sub spindle. In addition, tools can be placed facing either the main or sub spindle.

- ˙The special structural design uses a 90* angle for the turret carriage so you maintain superb rigidity and stability in machining. Additionally, this allows you to use a simpler controller specification, reducing programming complexity and saving you money at the same time.

- ˙The servo turrets are designed and built by CC Machinery especially for the CT series. This ensures maximum accuracy during machining, along with super fine finishes.

Applications

- Specification

Search

※ Design and specs subject to change without notice.