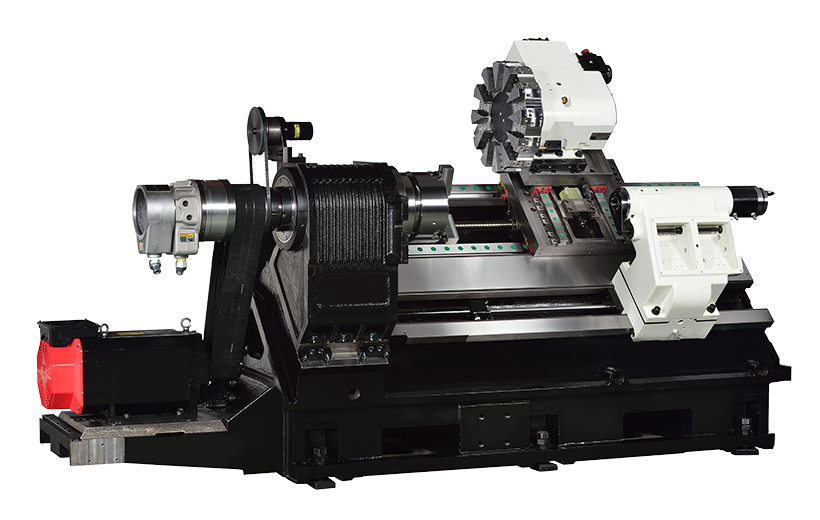

| Model | ML-250 |

|---|---|

| Controller | Fanuc |

| Length of spindle nose to turret | 713 mm |

| Max. turning. dia. | 400 mm |

| Swing over bed dia. | Ø590 mm |

| Turret swing over bed | Ø560 mm |

| Max. turning. length | 600 mm |

| Axis specifications | |

| X/Z-axis travel | 225 / 600 mm |

| X/Z-axis motor | 1.8 kw / 3.0 kw |

| X/Z-axis rapid travel speed | 20 / 24 m/min |

| Spindle | |

| Max. bar feeding dia. | 76 mm / 51 mm |

| Max. speed of spindle | 3500 rpm / 4500 rpm |

| Spindle chuck | 10" / 8" |

| Spindle motor | 15/18.5 kw |

| Spindle nose | A2-8 / A2-6 |

| Turret | |

| No. of tool | 12-station |

| Turret motor | 0.85 kw |

| Max. live tool motor | 3.7 kw |

| Max. live tool speed | 6000 rpm |

| O.D. tool size | □25 mm |

| I.D. tool size | Ø32 mm |

| Tailstock | |

| Tailstock travel | 600 mm |

| Quill stroke | 140 mm |

| Quill dia. | Ø85 mm |

| Power | |

| Coolant pump | 0.75 kw x1 |

| Hydraulic pump | 2 HP / 1.5 kw |

| Tank capacity | |

| Hydraulic tank | 20 L |

| Coolant tank | 340 L |

| Machine | |

| Voltage stabilizer / transformer | 30 KVA |

| Machine size (LxWxH)(includes chip conveyor) | 3812x1910x1940 mm |

| Machine weight (includes chip conveyor) | 5200 kg Machine:4749kg |

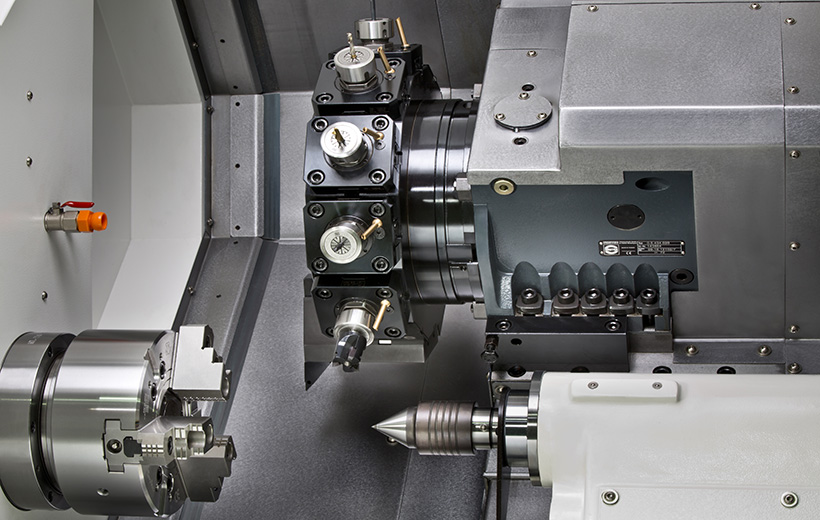

Turret Type - ML-250

1. 12 Station Power Turret

2. CS Servo Motor Driven

3. Precision Linear Guides & Ball screws

4. Programmable Tailstock

2. CS Servo Motor Driven

3. Precision Linear Guides & Ball screws

4. Programmable Tailstock

Features

- X/Z Axis Servo Motor Driven:

- X and Z axis using high-performance servo motor drive, displacement rate of 20m / 24m / min, to enhance the production rate and reduce the unnecessary time.

- It can place 8”/10” chuck. A-8 spindle nose, max spindle speed 3500 rpm. A-6 spindle nose, max spindle speed 4500 rpm.

- 12 Station Turret:

- The SAUTER power turret has loading capacity of 12 BMT 55 tools with indexing time 0.15 sec., high repeat indexing accuracy.

- Max high pressure capability is 50 bar. (option device)

- CS Servo Motor Driven:

- Spindle use belt drive with wide range spindle motor, providing high-speed spindle rotation has more stability, low-speed rotation to maintain maximum torque output.

- Precision Linear Guides & Ball screws:

- The turret use linear guide ways design, which can reduce the vibration in heavy cutting, ensure the long-term stability and maintain accuracy.

- Programmable Tailstock:

- The tailstock with MT-5 taper move by turret, can hold long workpieces firmly to making high precision parts with high accuracy.

Applications

- Specification

- Optional

Search

Optional

- Axial and radial live tool holder

- Transformer

- Oil skimmer

- Auto bar feeder interface

- Voltage stabilizer

- Oil Mist collector

- Coolant chiller