| Model | WTS-52Y2M | WTS-65Y2M |

|---|---|---|

| Controller | Mitsubishi | Fanuc | Mitsubishi | Fanuc |

| Max. manu. dia. | Ø 320 mm | Ø 320 mm |

| Standard turning. dia. | Ø 210 mm | Ø 210 mm |

| Distance between two center of spindle nose | 764 mm | 812 mm |

| Max. turning. length | 500 mm | 500 mm |

| Bar capacity | Ø 51 mm | Ø 65 mm |

| Axis specifications | ||

| B-axis travel | 500 mm | 500 mm |

| E-axis travel | 170 mm | 170 mm |

| X1/X2-axis travel | 215 / 230 mm | 215 / 230 mm |

| Z1/Z2-axis travel | 500 / 500 mm | 500 / 500 mm |

| Y1/Y2-axis travel | ± 50 / ± 50 mm | ± 50 / ± 50 mm |

| E-axis motor | M:2.2 kw / F:2.7 kw | M:2.2 kw / F:2.7 kw |

| X/Y/Z-axis motor | M:2.2 kw / F:2.7 kw | M:2.2 kw / F:2.7 kw |

| X/Y/Z-axis rapid travel speed | 16 / 6 / 40 m/min | 16 / 6 / 40 m/min |

| B-axis rapid travel speed | 40 m/min | 40 m/min |

| E-axis rapid travel speed | 6 m/min | 6 m/min |

| Min. input unit | 0.001 mm | 0.001 mm |

| Spindle | ||

| Max. speed of spindle | 6000 rpm | 4000 rpm |

| Spindle motor | M:7.5/11 kw F:13/15 kw | M:7.5/11 kw F:18/22 kw |

| Center height | 1180 mm | 1180 mm |

| Spindle nose | A2-5 | A2-6 |

| Chuck size | 6" | 8" |

| Sub spindle | ||

| Max. speed of sub spindle | 6000 rpm | 4000 rpm |

| Sub spindle motor | M:7.5/11 kw F:13/15 kw | M:7.5/11 kw F:18/22 kw |

| Sub spindle nose | A2-5 | A2-6 |

| Sub chuck size | 6" | 8" |

| L, R, C | ||

| Min. moving unit | 0.001 mm | 0.001 mm |

| C-axis rapid travel rate | 600 min⁻¹ | 600 min⁻¹ |

| Live tool turret | ||

| Turret station | 16-positions | 16-positions |

| O.D. tool | □20 mm | □20 mm |

| I.D. tool | Ø 25 mm | Ø 25 mm |

| Rotating mode | Single tool transmission | Single tool transmission |

| Live tool rpm | 60~600 min⁻¹ | 60~600 min⁻¹ |

| Live tool motor | M:3.7/5.5 kw F:4.5 kw | M:3.7/5.5 kw F:4.5 kw |

| No. of live tool | 16*2 | 16*2 |

| Collet size | ERØ25A | ERØ25A |

| Tool holder & tool size | BMT55 | BMT55 |

| Tailstock | ||

| Quill stroke | 500 mm | - |

| Pump | ||

| Hydraulic pump | 3HP / 2.2kw*2 | 3HP / 2.2kw*2 |

| Quill stroke | 1.57HP / 1.17kW / 60Hz | 1.57HP / 1.17kW / 60Hz |

| Tank capacity | ||

| Hydraulic tank | 65 L | 65 L |

| Coolant tank | 440 L | 440 L |

| Machine | ||

| Voltage stabilizer / transformer | 60 KVA | 60 KVA |

| Machine size(LxWxH) (includes chip conveyor) | 4262*2390*2230 mm | 4262*2390*2230 mm |

| Machine N.W.(includes chip conveyor) | 10500 kg Machine:9948 kg | 10500 kg Machine:9948 kg |

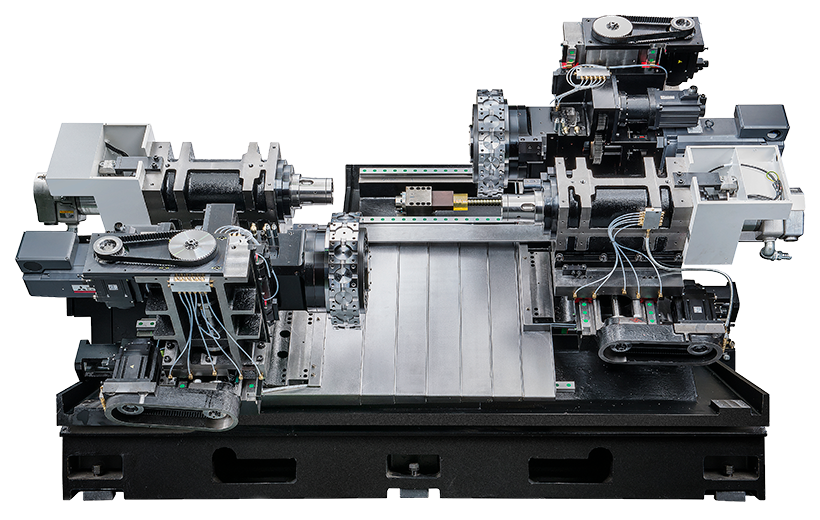

Turret Type-WTS

1. Double Y-Axis, 32 Live Tools

2. Sub Spindle E-Axis Shifting Function

3. Fixed Tailstock

2. Sub Spindle E-Axis Shifting Function

3. Fixed Tailstock

Features

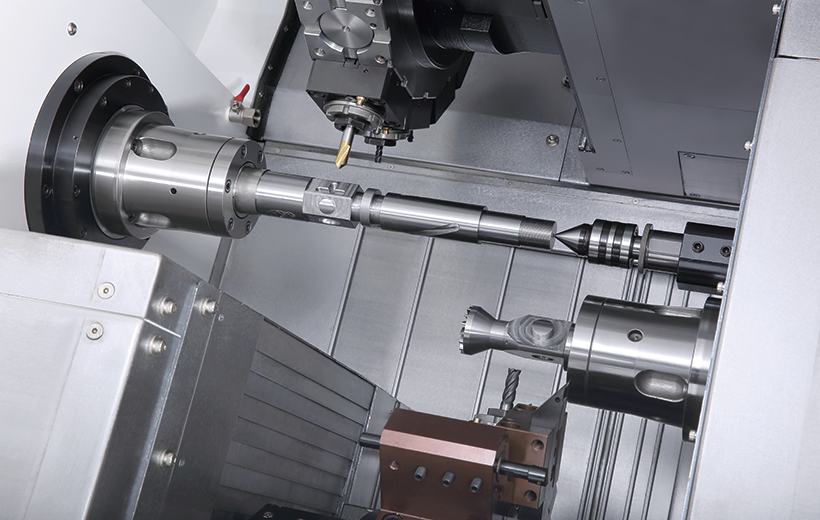

- An E-axis allows for the second spindle and tailstock to move up and down. This provides an independent working environment for machining.

- The WTS comes with two BMT55 16-station power turrets that can also be equipped with differenttypes of BMT55 systems.The upper and lower turrets can work independently with spindles 1 and 2.

- The special structural design of the WTS uses a rigid 90 angle for the turret carriage, providing excellent chip flushing and removal.

- A fixed tailstock for long workpieces keeps them parallel, and improves precision and stability during machining.

Applications

- Specification

- Optional

Search

Optional

- 6” / 8” hydraulic chuck

- Volteage stabilizer / trans for mer

- Bar feeder

- Mitsubish robot

- Auto door

- Axial and radial live tool holder

- High pressure coolant device

- Oil mist collector

- Gantry type robot