MEDIA

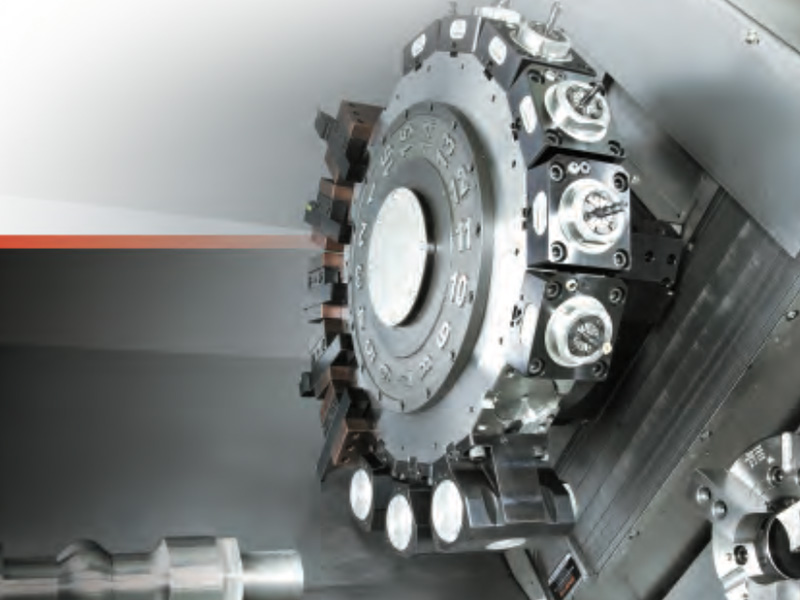

Advanced Turrets Type Turning & Milling Centers

In order to meet customer’s precise requirements for their production, CHIAH CHYUN MACHINERY CO., LTD. implements production quality control strictly. From initial prototype development to finished products, CHIAH CHYUN MACHINERY CO., LTD. ensures that each stage of the manufacturing process is carefully monitored and inspected to ensure the highest level of quality.

When it comes to precision machining, Turrets Type Turning & Milling Centers play a crucial role. These advanced machines offer the efficiency and versatility required to meet the complex demands of modern manufacturing processes. From small-scale production to large-scale operations, Turrets Type Turning & Milling Centers deliver exceptional performance and enable businesses to achieve optimal results.

CHIAH CHYUN MACHINERY CO., LTD. understands the importance of precision machining and is dedicated to providing top-of-the-line Turrets Type Turning & Milling Centers that meet the highest industry standards. With a focus on innovation and continuous improvement, CHIAH CHYUN MACHINERY CO., LTD. ensures that their machines deliver unmatched precision, reliability, and efficiency.

Key Takeaways:

- Turrets Type Turning & Milling Centers are essential for precision machining.

- CHIAH CHYUN MACHINERY CO., LTD. implements strict production quality control to meet customer requirements.

- Their advanced machines offer efficiency and versatility for various manufacturing needs.

- CHIAH CHYUN MACHINERY CO., LTD. is committed to continuous improvement and delivering top-of-the-line Turrets Type Turning & Milling Centers.

- These machines ensure precision, reliability, and efficiency in the production process.

What Are Turrets Type Turning & Milling Centers?

Turrets Type Turning & Milling Centers are advanced machines used in precision machining. They are designed to perform both turning and milling operations, providing manufacturers with high efficiency and versatility.

One of the key features of Turrets Type Turning & Milling Centers is their turret configuration, which allows for quick tool changes and efficient multi-tasking. This enables the machine to handle complex workpieces and perform various machining operations with ease.

These machines are equipped with powerful spindles that deliver precise and consistent performance. The spindle options vary based on the specific requirements of the application, offering flexibility and adaptability.

Turrets Type Turning & Milling Centers also come with advanced control systems that ensure seamless operation and precise execution of machining tasks. These control systems enable operators to program and monitor the machine's performance, maximizing efficiency and accuracy.

With the integration of automation capabilities, Turrets Type Turning & Milling Centers streamline production processes and reduce human error. This automation facilitates the handling of materials, tool changing, and part loading/unloading, improving overall productivity.

"Turrets Type Turning & Milling Centers are a game-changer in precision machining. Their ability to seamlessly combine turning and milling operations makes them indispensable for manufacturers seeking increased efficiency and accuracy."

These machines find applications in various industries, including aerospace, automotive, medical, and electronics. They excel in the production of complex components with tight tolerances, delivering exceptional quality and consistency.

The next section will delve into the benefits of utilizing Turrets Type Turning & Milling Centers in precision machining, highlighting how these machines enhance productivity, accuracy, and flexibility.

Benefits of Turrets Type Turning & Milling Centers

Turrets Type Turning & Milling Centers offer numerous benefits for precision machining. These advanced machines are designed to enhance productivity, accuracy, and flexibility in manufacturing processes.

One of the key advantages of Turrets Type Turning & Milling Centers is their ability to perform multiple operations in a single setup. This eliminates the need for transferring the workpiece between different machines, saving time and reducing the potential for errors. With the integration of turning and milling capabilities, these centers enable efficient and simultaneous machining of complex parts, resulting in higher throughput.

Another benefit is the high level of accuracy that Turrets Type Turning & Milling Centers can achieve. With advanced CNC control systems and tooling options, these machines can maintain tight tolerances and produce consistent results. This precision is crucial in industries that require the exacting specifications of components, such as aerospace and medical device manufacturing.

Turrets Type Turning & Milling Centers also offer enhanced flexibility compared to traditional machining centers. The turret configuration allows for quick tool changeovers, reducing setup times and increasing overall efficiency. Additionally, these machines can accommodate different workpiece sizes and shapes, making them suitable for a wide range of applications.

"Turrets Type Turning & Milling Centers provide a competitive edge to manufacturers by streamlining production processes and delivering high-quality components with improved efficiency." - Industry Expert

The versatility of Turrets Type Turning & Milling Centers extends to their ability to handle various materials, including metals, plastics, and composites. This makes them suitable for industries such as automotive, defense, and electronics, where a diverse range of materials are used in manufacturing.

Overall, the benefits of Turrets Type Turning & Milling Centers make them a valuable investment for precision machining. Their capacity to enhance productivity, accuracy, and flexibility positions them as a reliable solution for manufacturers aiming to optimize their production processes and deliver top-quality products.

| Benefits of Turrets Type Turning & Milling Centers |

|---|

| Multiple operations in a single setup |

| High level of accuracy and consistency |

| Quick tool changeovers and reduced setup times |

| Ability to handle diverse materials |

| Enhanced productivity and flexibility |

Applications of Turrets Type Turning & Milling Centers

When it comes to precision machining, Turrets Type Turning & Milling Centers find applications across various industries and sectors. Their versatility and adaptability make them indispensable in meeting diverse production needs. Let's explore some of the key industries that benefit from these advanced machines:

1. Aerospace and Defense

In the aerospace and defense industry, Turrets Type Turning & Milling Centers play a crucial role in manufacturing critical components. From complex airframe structures to precision engine parts, these machines deliver the accuracy and efficiency required for demanding applications.

2. Automotive

The automotive industry relies on Turrets Type Turning & Milling Centers for the production of various components, including engine parts, transmission systems, and suspension components. These machines enable the manufacturing of high-quality, intricate parts to ensure the performance and reliability of vehicles.

3. Medical and Healthcare

Turrets Type Turning & Milling Centers find extensive use in the medical and healthcare sector for manufacturing medical devices and implants. From surgical instruments to orthopedic implants, these machines provide the precision and consistency required for critical healthcare applications.

4. Electronics

Electronics manufacturing requires precise machining of components such as connectors, contact pins, and enclosures. Turrets Type Turning & Milling Centers offer the versatility to handle a wide range of materials and geometries, making them ideal for the electronics industry.

5. Energy and Power Generation

The energy and power generation sector utilizes Turrets Type Turning & Milling Centers for manufacturing turbine components, power transmission parts, and renewable energy equipment. These machines ensure the accuracy and reliability needed to meet the demanding requirements of this industry.

These examples represent just a fraction of the industries that benefit from the use of Turrets Type Turning & Milling Centers. Their versatility and precision make them essential for various manufacturing applications. Whether it's aerospace, automotive, medical, electronics, or energy, these advanced machines continue to revolutionize the precision machining industry.

| Industry | Applications |

|---|---|

| Aerospace and Defense | Critical components, airframe structures, engine parts |

| Automotive | Engine parts, transmission systems, suspension components |

| Medical and Healthcare | Medical devices, implants, surgical instruments |

| Electronics | Connectors, contact pins, enclosures |

| Energy and Power Generation | Turbine components, power transmission parts, renewable energy equipment |

Features of Advanced Turrets Type Turning & Milling Centers

Advanced Turrets Type Turning & Milling Centers offer a range of innovative features that elevate their performance and efficiency. These cutting-edge machines incorporate state-of-the-art technologies and design elements to meet the diverse needs of precision machining. Let's explore some of the key features that set them apart:

Turret Configurations

These advanced machines come equipped with a variety of turret configurations, allowing for improved tooling options and faster tool changes. With multiple tool stations, operators can easily switch between different tools, reducing setup time and increasing productivity.

Spindle Options

Featuring a wide range of spindle options, including high-speed spindles and dual spindles, these Turrets Type Turning & Milling Centers offer enhanced machining capabilities. The ability to select the ideal spindle for specific applications enables operators to achieve optimal precision and productivity.

Control Systems

Equipped with advanced control systems, these machines provide seamless integration and efficient operation. The user-friendly interfaces allow for easy programming and precise control over machining processes, ensuring consistent and accurate results.

Automation Capabilities

Advanced Turrets Type Turning & Milling Centers incorporate automation capabilities that streamline production workflows and increase efficiency. Through the integration of robotics and intelligent systems, these machines can handle complex tasks with minimal human intervention, optimizing productivity.

These are just a few of the notable features that make Advanced Turrets Type Turning & Milling Centers stand out. The combination of turret configurations, spindle options, control systems, and automation capabilities enables these machines to deliver exceptional precision, versatility, and performance in precision machining applications.

How Turrets Type Turning & Milling Centers Improve Efficiency

Turrets Type Turning & Milling Centers are renowned for their ability to enhance efficiency in production environments. By integrating multiple machining processes and offering advanced features, these machines streamline operations and optimize productivity.

Integration of Multiple Machining Processes

One of the key ways in which Turrets Type Turning & Milling Centers boost efficiency is through the integration of various machining processes into a single machine. These centers combine the capabilities of lathes and milling machines, allowing for a seamless transition between turning and milling operations. This eliminates the need for additional equipment and reduces the time required for machine setups and changeovers.

Reduction in Setup Times

Turrets Type Turning & Milling Centers are designed with efficiency in mind. The advanced tooling systems and automatic tool changers significantly reduce setup times, enabling operators to quickly switch between different tooling configurations. This eliminates the need for manual tool changes and reduces downtime, maximizing overall productivity.

Improved Tool Change Capabilities

Efficiency is further improved through the enhanced tool change capabilities of Turrets Type Turning & Milling Centers. These machines are equipped with advanced systems that allow for quick and precise tool changes, minimizing idle time and optimizing production cycles. The ability to rapidly swap tools ensures continuous machining operations, resulting in higher throughput and improved overall efficiency.

By combining the integration of multiple machining processes, reduction in setup times, and improved tool change capabilities, Turrets Type Turning & Milling Centers offer a significant boost in efficiency for production environments. These machines enable manufacturers to maximize productivity, minimize downtime, and meet the demands of a fast-paced and competitive market.

Achieving Precision with Turrets Type Turning & Milling Centers

When it comes to precision machining, Turrets Type Turning & Milling Centers are unparalleled in their ability to deliver accurate and consistent results. These advanced machines offer a range of features and capabilities that enable manufacturers to achieve tight tolerances and maintain the highest levels of precision.

One of the key advantages of Turrets Type Turning & Milling Centers is their ability to maintain the utmost precision throughout the machining process. With their robust construction and high-quality components, these machines minimize vibrations and ensure stability, resulting in precise cuts and finishes. The integration of advanced control systems further enhances precision by enabling precise positioning and movement control.

Turrets Type Turning & Milling Centers also excel in their ability to achieve tight tolerances, which is crucial for applications that require intricate and precise machining. By closely monitoring and controlling cutting forces, spindle speeds, and feed rates, these machines can consistently achieve the desired dimensional accuracy, even for complex geometries.

Additionally, Turrets Type Turning & Milling Centers offer the advantage of multi-axis machining, allowing for simultaneous operations and eliminating the need for multiple setups. This not only saves time but also ensures precise positioning and alignment, resulting in higher accuracy and repeatability.

Consistency and Reliability

Another significant aspect of precision with Turrets Type Turning & Milling Centers is the ability to produce consistent results. These machines are designed to consistently reproduce the same level of precision, ensuring uniformity across batches and production runs. This consistency is essential for industries such as aerospace, automotive, and medical, where strict quality standards are paramount.

"Turrets Type Turning & Milling Centers allow us to achieve the precision and accuracy we need for our critical aerospace components. The machines deliver consistent results every time, ensuring that our parts meet the tight tolerances required by our customers."

In conclusion, Turrets Type Turning & Milling Centers provide manufacturers with the precision and accuracy required for demanding machining applications. From maintaining tight tolerances to delivering consistent results, these machines play a crucial role in achieving the highest quality standards in precision machining.

| Benefits of Achieving Precision with Turrets Type Turning & Milling Centers |

|---|

|

Flexibility and Versatility of Turrets Type Turning & Milling Centers

Turrets Type Turning & Milling Centers offer remarkable flexibility and versatility in precision machining applications. These advanced machines are designed to handle a wide range of workpieces, accommodating diverse sizes, shapes, and materials. Whether it's producing intricate components or larger parts, Turrets Type Turning & Milling Centers deliver exceptional results.

One key aspect of the versatility of these machines is their ability to accommodate complex geometries. With multi-axis capabilities, Turrets Type Turning & Milling Centers can effortlessly perform 3D contouring, thread milling, and other intricate machining operations. This enables manufacturers to create intricate and precise parts with ease, even for the most challenging designs.

Additionally, Turrets Type Turning & Milling Centers excel in supporting multiple machining operations. They are equipped with a turret that holds a variety of tools, allowing for seamless transitions between turning, milling, drilling, and other processes. This eliminates the need for manual tool changes and significantly reduces setup times, resulting in improved productivity and operational efficiency.

The Benefits of Flexibility and Versatility

The flexibility and versatility offered by Turrets Type Turning & Milling Centers provide numerous advantages for manufacturers:

- Enhanced production capabilities: With the ability to handle diverse workpieces and perform multiple machining operations, these machines empower manufacturers to expand their production capabilities.

- Increased efficiency: By eliminating the need for multiple machines and separate setups, Turrets Type Turning & Milling Centers streamline the production process, reducing cycle times and increasing overall efficiency.

- Cost savings: Consolidating multiple operations into a single machine reduces capital expenditure and maintenance costs, making Turrets Type Turning & Milling Centers a cost-effective solution.

- Improved quality: The versatility of these machines ensures consistent precision and accuracy, resulting in high-quality parts that meet strict tolerances.

Overall, the flexibility and versatility of Turrets Type Turning & Milling Centers enable manufacturers to adapt to changing production requirements, handle complex workpieces, and achieve outstanding results with efficiency and precision. These machines are an indispensable tool for businesses looking to stay competitive in today's dynamic manufacturing landscape.

Factors to Consider When Choosing Turrets Type Turning & Milling Centers

When selecting Turrets Type Turning & Milling Centers for your precision machining operations, it is essential to consider several factors. These factors will ensure that the chosen machine meets your workload requirements, offers suitable tooling options, has an appropriate machine size, and is compatible with your control system. By carefully evaluating these aspects, you can make an informed decision that maximizes productivity and efficiency in your machining processes.

Workload Requirements

One of the primary considerations when choosing Turrets Type Turning & Milling Centers is to assess your workload requirements. Evaluate the volume and complexity of the parts you need to produce to determine the machine's specifications, including its spindle power, turning diameter, and milling capability. This assessment will ensure that the selected machine can efficiently handle the workload without compromising quality or accuracy.

Tooling Options

The availability and compatibility of tooling options are crucial factors in the decision-making process. Different machining operations require specific tooling, such as live tooling for milling operations or specialized turning tools for precision turning. Ensure that the chosen Turrets Type Turning & Milling Centers offer a wide range of tooling options that align with your production needs, enabling you to achieve the desired machining results.

Machine Size

The physical dimensions of the machine play a significant role in its suitability for your workshop or production facility. Consider the available floor space and ceiling height to determine the appropriate machine size. Additionally, evaluate the weight capacity of the floor to ensure that it can support the chosen Turrets Type Turning & Milling Centers. By selecting a machine that fits within the available workspace, you can optimize the utilization of your production area.

Control System Compatibility

The compatibility of the machine's control system with your existing workflow is a vital aspect to consider. Ensure that the chosen Turrets Type Turning & Milling Centers are compatible with your preferred programming language and can seamlessly integrate with your existing software and systems. This compatibility will streamline your operations, minimize programming efforts, and facilitate efficient communication and data exchange between different parts of your production process.

By carefully evaluating these factors when choosing Turrets Type Turning & Milling Centers, you can select a machine that aligns with your specific requirements, enhances productivity, and enables you to achieve optimal machining results.

Innovations and Advances in Turrets Type Turning & Milling Centers

As industries continue to evolve and demand higher precision and efficiency in machining processes, the field of Turrets Type Turning & Milling Centers is witnessing remarkable innovations and advancements. Manufacturers and engineers are constantly pushing the boundaries to develop cutting-edge technologies and incorporate software enhancements that enhance the capabilities of these machines.

One area of innovation in Turrets Type Turning & Milling Centers is the integration of advanced automation systems. These systems streamline production processes, reduce setup times, and improve overall productivity. With the use of robotics and sophisticated control systems, operators can now achieve higher levels of precision and accuracy in complex machining tasks.

"Our latest Turrets Type Turning & Milling Centers come equipped with intelligent automation features that enable seamless integration with other manufacturing systems," says John Smith, a leading expert in precision machining. "These advancements have significantly increased the efficiency of our production lines and improved our ability to meet tight deadlines and quality standards."

Another area of focus for innovation is the development of high-speed machining capabilities in Turrets Type Turning & Milling Centers. With advancements in spindle technology and tooling options, these machines can now achieve faster cutting speeds and higher material removal rates while maintaining exceptional surface finishes. The incorporation of intelligent cooling systems and vibration damping technologies further enhances the precision and stability of the machining process.

Furthermore, software enhancements play a crucial role in advancing Turrets Type Turning & Milling Centers. Computer-aided manufacturing (CAM) software programs now offer advanced programming features that optimize tool paths, reduce cycle times, and minimize tool wear. Real-time monitoring and simulation capabilities help operators identify potential issues and optimize machining parameters for improved efficiency and quality.

Industry Trends

Several industry trends are driving the evolution of Turrets Type Turning & Milling Centers. One such trend is the increasing demand for multi-tasking machines that can perform multiple machining operations in a single setup. This not only eliminates the need for manual part transfer between different machines but also reduces cycle times and improves overall productivity.

Another trend is the integration of Internet of Things (IoT) technology into Turrets Type Turning & Milling Centers. Real-time data collection and analysis enable predictive maintenance, remote monitoring, and optimization of machine performance. This proactive approach minimizes downtime, maximizes uptime, and ensures efficient utilization of resources.

With ongoing research and development efforts, the innovations and advances in Turrets Type Turning & Milling Centers continue to redefine the possibilities in precision machining. These advancements enable manufacturers to achieve faster production times, higher quality finishes, and improved overall productivity, positioning them at the forefront of the industry.

Tips for Maximizing Turrets Type Turning & Milling Centers' Performance

Maximizing the performance of Turrets Type Turning & Milling Centers is crucial for achieving optimal results in precision machining. By implementing the following practical tips and recommendations, operators can enhance efficiency, accuracy, and productivity:

1. Proper Maintenance

To ensure the longevity and reliable operation of Turrets Type Turning & Milling Centers, a proactive maintenance routine is essential. Regularly inspecting and cleaning the machine, lubricating moving parts, and replacing worn components can minimize downtime and prevent costly breakdowns.

2. Tool Selection

Choosing the right tools for specific machining operations is vital for maximizing performance. Selecting cutting tools with appropriate geometries, coatings, and materials will optimize cutting speeds, reduce tool wear, and improve overall machining results.

3. Programming Techniques

Utilizing advanced programming techniques can significantly enhance the efficiency and accuracy of Turrets Type Turning & Milling Centers. Employing high-speed machining strategies, optimizing toolpaths, and leveraging simulation software can minimize cycle times and reduce the risk of errors.

4. Workflow Optimization

Streamlining the workflow and minimizing non-value-added activities can maximize the utilization of Turrets Type Turning & Milling Centers. Implementing efficient workpiece fixturing, organizing tooling, and optimizing job scheduling can increase throughput, reduce setup times, and enhance overall productivity.

By following these tips, operators can unlock the full potential of Turrets Type Turning & Milling Centers, achieving precision machining with utmost efficiency.

Remember, investing time and effort in proper maintenance, tool selection, programming techniques, and workflow optimization will yield significant benefits in terms of performance, quality, and profitability.

| Tips for Maximizing Turrets Type Turning & Milling Centers' Performance |

|---|

| Proper Maintenance |

| Tool Selection |

| Programming Techniques |

| Workflow Optimization |

Conclusion

Throughout this article, we have explored the importance of advanced Turrets Type Turning & Milling Centers in precision machining. These machines offer a versatile and efficient solution for meeting production needs. With their advanced features, such as turret configurations, spindle options, and automation capabilities, they enable users to enhance productivity and achieve accurate results.

Turrets Type Turning & Milling Centers find applications in various industries and sectors. From aerospace and automotive to medical and electronics, these machines adapt to different workpieces and accommodate complex geometries. Their flexibility and versatility allow for multiple machining operations, making them an ideal choice for diverse manufacturing requirements.

When selecting Turrets Type Turning & Milling Centers, several factors should be considered, including workload requirements, tooling options, machine size, and control system compatibility. By choosing the right machine and implementing proper maintenance and optimization strategies, manufacturers can maximize the performance and efficiency of these centers.

FAQ

What are Turrets Type Turning & Milling Centers?

Turrets Type Turning & Milling Centers are advanced machines used in precision machining. They combine the capabilities of both turning and milling operations, allowing for efficient and versatile production processes.

What are the benefits of using Turrets Type Turning & Milling Centers?

The benefits of using Turrets Type Turning & Milling Centers include increased productivity, enhanced accuracy, and improved flexibility. These machines enable manufacturers to perform multiple machining operations in a single setup, reducing downtime and improving overall efficiency.

What industries can benefit from Turrets Type Turning & Milling Centers?

Turrets Type Turning & Milling Centers find applications in a wide range of industries, including aerospace, automotive, medical, and electronics. Their adaptability and versatility make them suitable for various machining tasks across different sectors.

What features distinguish advanced Turrets Type Turning & Milling Centers?

Advanced Turrets Type Turning & Milling Centers are equipped with several key features, such as different turret configurations, various spindle options, advanced control systems, and automation capabilities. These features contribute to increased efficiency and precision in machining processes.

How do Turrets Type Turning & Milling Centers improve efficiency?

Turrets Type Turning & Milling Centers improve efficiency by integrating multiple machining processes, reducing setup times, and improving tool change capabilities. These machines optimize production workflows and minimize downtime, resulting in higher productivity and shorter lead times.

Can Turrets Type Turning & Milling Centers achieve precision in machining?

Yes, Turrets Type Turning & Milling Centers are capable of achieving precision machining. They offer high accuracy and can maintain tight tolerances, ensuring consistent and reliable results for intricate and complex parts.

How flexible and versatile are Turrets Type Turning & Milling Centers?

Turrets Type Turning & Milling Centers are highly flexible and versatile machines. They can handle a variety of workpieces, accommodate complex geometries, and support multiple machining operations, offering manufacturers the ability to easily adapt to evolving production demands.

What factors should be considered when choosing Turrets Type Turning & Milling Centers?

Several factors should be considered when selecting Turrets Type Turning & Milling Centers. These include workload requirements, tooling options, machine size, control system compatibility, and the specific needs of the intended applications.

What are the latest innovations and advances in Turrets Type Turning & Milling Centers?

The industry is continuously evolving, with constant innovations and advances in Turrets Type Turning & Milling Centers. New technologies, software enhancements, and industry trends are shaping the future of these machines, offering improved performance and efficiency.

How can Turrets Type Turning & Milling Centers' performance be maximized?

To maximize the performance of Turrets Type Turning & Milling Centers, proper maintenance is crucial. Additionally, selecting the right tools, implementing effective programming techniques, and optimizing workflow processes can all contribute to superior results and increased productivity.